# Rain Gauge: A Comprehensive Overview of Its Design and Functionality

## Introduction to Rain Gauges

A rain gauge is a meteorological instrument used to measure the amount of liquid precipitation that falls over a specific area during a defined time period. These devices play a crucial role in weather monitoring, agriculture, hydrology, and climate research.

## Types of Rain Gauges

### Standard Rain Gauges

The most common type is the standard rain gauge, which consists of a funnel that collects precipitation and directs it into a measuring tube. The narrow tube amplifies the water level, allowing for more precise measurements.

### Tipping Bucket Rain Gauges

These electronic gauges feature a small bucket that tips when it collects a set amount of precipitation (typically 0.01 inches or 0.2 mm). Each tip is recorded electronically, providing real-time rainfall data.

### Weighing Rain Gauges

Weighing gauges measure precipitation by weighing the collected water. They’re particularly useful for measuring snowfall by melting it first and then measuring the equivalent water content.

## Key Components of a Rain Gauge

The basic components of most rain gauges include:

- A collection funnel to gather precipitation

- A measuring cylinder or mechanism to quantify the collected water

- A mounting system to position the gauge properly

- In electronic models: data recording and transmission components

## How Rain Gauges Work

The fundamental principle behind rain gauges is simple: they collect falling precipitation in a standardized container and measure the depth of the accumulated water. This measurement is typically expressed in millimeters or inches of rainfall.

For accurate measurements, rain gauges must be placed in open areas away from obstructions like trees or buildings that might interfere with precipitation collection. The opening of the gauge should be horizontal and positioned at a standard height above ground level.

## Importance of Proper Installation

Location Considerations

Proper installation is critical for accurate rainfall measurements. The gauge should be placed:

- On level ground

- At least twice as far from obstructions as their height

- In an area representative of the surrounding terrain

Mounting Height

Standard mounting height is typically 30 cm to 1 meter above ground to prevent splashing from the ground while minimizing wind effects on measurement accuracy.

## Maintenance and Calibration

Regular maintenance ensures accurate measurements:

- Clean the gauge periodically to prevent debris buildup

- Check for leaks or damage

- Calibrate the gauge according to manufacturer specifications

- Empty the gauge after each measurement period

## Applications of Rain Gauge Data

Rainfall measurements have numerous applications:

- Weather forecasting and climate studies

- Agricultural planning and irrigation management

- Flood prediction and water resource management

- Hydrological modeling

- Urban planning and drainage system design

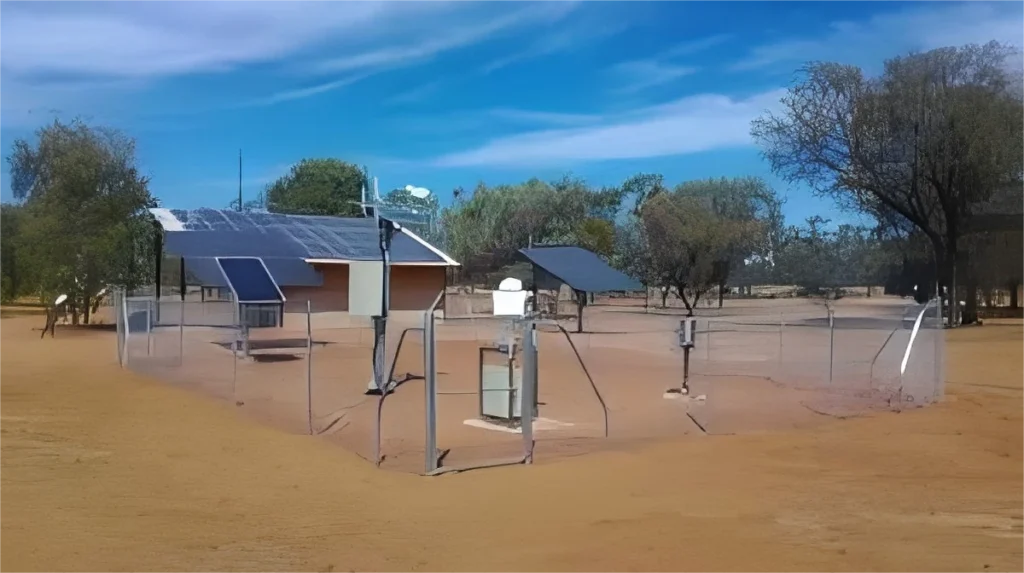

## Technological Advancements

Modern rain gauges incorporate advanced features:

- Wireless data transmission

- Integration with weather stations

- Automated data logging

- Remote monitoring capabilities

## Conclusion

Rain gauges remain essential tools for measuring precipitation despite their simple concept. From basic manual models to sophisticated electronic systems, these instruments provide valuable data that supports numerous scientific, agricultural, and environmental applications. Proper selection, installation, and maintenance are key to obtaining accurate rainfall measurements that can inform important decisions across various sectors.

Keyword: rain gauge description